Corrosion in subsea pipelines and anti-corrosion solutions to ensure safe operation of Vietsovpetro’s oil and gas fields

Abstract

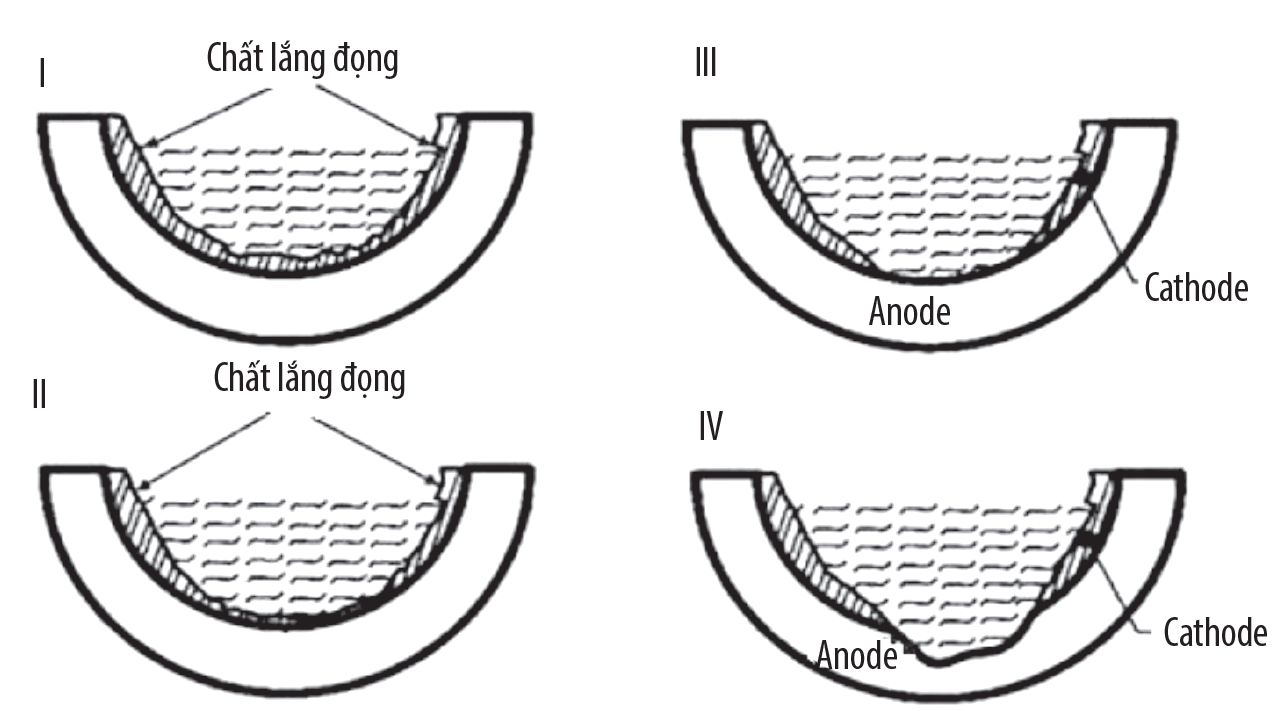

The subsea pipelines of Vietsovpetro’s offshore fields in Block 09-1 were made of carbon steel. These pipelines have been operating in high content of produced water and corrosive impurities for a long period (many pipelines for over 25 years, which exceed their designed lifetime)

which implies very high risks of leakage. Corrosion tests in the laboratory and visual observation of the actual pipeline samples revealed the highest corrosion rate at the bottom of the pipelines, and the positions where water or corrosive products accumulate/stagnate. Pig launching

and receiving systems have been designed, installed, and successfully operated in two oil and gaslift pipelines of Bach Ho field to monitor and control corrosion, clean subsea pipelines to minimise corrosion under deposit layers and optimise the effectiveness of the corrosion inhibitors.

This article analyses the current corrosion inside the subsea pipelines of Block 09-1, the influencing factors, the corrosion mechanism, and mitigation methods to ensure the safe operation of Vietsovpetro’s oil and gas fields.

References

James Speight, Oil and gas corrosion prevention (1st edition). Gulf Professional Publishing, 2014.

Нгуен Тхук Кханг, “Разработка технологии транспорта нефти, исключающей расслоение

наднжности эксплуатации нефтепроводов на шельфе Вьетнам”, Диссертация на соискание ученой степени кандидата технических наук, Москва, 2000.

Vietsovpetro, “Hoàn thiện công tác chống ăn mòn cho các công trình dầu khí biển của Vietsovpetro”.

Weatherford, “Đánh giá độ nhiễm vi khuẩn trong các thiết bị của hệ thống thu gom vận chuyển dầu tại các giàn công nghệ trung tâm và tàu chứa dầu của của Vietsovpetro”, 1234 109/N-N5SP5-Weathas.

Lekan Taofeek Popoola, Alhaji Shehu Grema, Ganiyu Kayode Latinwo, Babagana Gutti, and Adebori

Saheed Balogun, “Corrosion problems during oil and gas production and its mitigation”, International Journal of Industrial Chemistry, Vol. 4, No. 35, 2013. DOI: 10.1186/2228-5547-4-35.

ASTM International, “Standard practice for preparing, cleaning, and evaluating corrosion test specimens”, ASTM G1-03, 2017.

1. The Author assigns all copyright in and to the article (the Work) to the Petrovietnam Journal, including the right to publish, republish, transmit, sell and distribute the Work in whole or in part in electronic and print editions of the Journal, in all media of expression now known or later developed.

2. By this assignment of copyright to the Petrovietnam Journal, reproduction, posting, transmission, distribution or other use of the Work in whole or in part in any medium by the Author requires a full citation to the Journal, suitable in form and content as follows: title of article, authors’ names, journal title, volume, issue, year, copyright owner as specified in the Journal, DOI number. Links to the final article published on the website of the Journal are encouraged.