Approaches to enhance the value of Ca Voi Xanh gas via its transformation into nanocarbon materials

Abstract

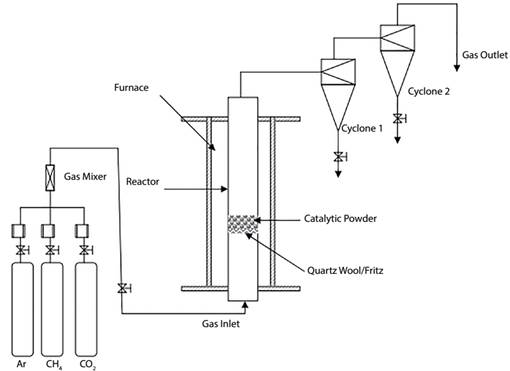

Ca Voi Xanh gas has high contents of impurities, namely H2S, CO2 and N2. The transformation of this gas into high-value products is a potential approach to enhance its value without pre-treatment. In fact, it is a promising feedstock for nanocarbon production, including carbon nanotubes (CNT) and carbon nanofibres (CNF). Their applications can be found in various areas of which markets are promising. Two methods for nanocarbon production can be considered, namely methane decomposition and dry reforming of methane. Methane decomposition brings higher nanocarbon yields while dry reforming of methane can produce better quality nanocarbon products. A number of issues need to be solved before these processes can be commercialised, such as improvements of nanocarbon yields and their recovery methods.

References

2. Robert A.Dagle, Vanessa Dagle, Mark D.Bearden, Jamelyn D.Holladay, Theodore R.Krause, Shabbir Ahmed. An overview of natural gas conversion technologies for

co-production of hydrogen and value-added solid carbon products. 2017.

3. R.Dagle, V.Dagle, M.Bearden, J.Holladay, T.Krause, S.Ahmed. R&D opportunities for development of natural gas conversion technologies for co-production of hydrogen and

value-added solid carbon products. Argonne National Lab Report. 2017.

4. Marketsandmarkets. Carbon nanotubes market worth 8.70 billion USD by 2022. www.marketsandmarkets. com/PressReleases/carbon-nanotubes.asp.

5. Tiago P.Braga, Regina C.R.Santos, Barbara M.C.Sales, Bruno R.da Silva, Antônio N.Pinheiro, Edson R.Leite, Antoninho Valentini. CO2 mitigation by carbon

nanotube formation during dry reforming of methane analyzed by factorial design combined with response surface methodology. Chinese Journal of Catalysis. 2014; 35(4):

p. 514 - 523.

6. Zirui Jia, Kaichang Kou, Ming Qin, Hongjing Wu, Fabrizio Puleo, Leonarda Liotta. Controllable and largescale synthesis of carbon nanostructures: A review on bamboo-like nanotubes. 2017; 7(9): p. 256 - 276.

7. Kapil Moothi. Carbon nanotube production from greenhouse gases during syngas synthesis. University of the Witwatersrand. 2009.

8. Steven Corthals, Jasper Van Noyen, Jan Geboers, Tom Vosch, Duoduo Liang, Xiaoxing Ke, Johan Hofkens, Gustaaf Van Tendeloo, Pierre Jacobs, Bert Sels. The beneficial effect of CO2 in the low temperature synthesis of high quality carbon nanofibers and thin multiwalled carbon nanotubes from CH4 over Ni catalysts. Carbon. 2012; 50(2): p. 372 - 384.

9. S.Shukrullah, Norani Muti Mohammed, Maizatul Shaharun, Muhammad Yasin Naz. Mass production of carbon nanotubes using fluidized bed reactor: A short review. Trends in Applied Sciences Research. 2014; 9(3): p. 121 - 131.

10. Noel Peter Bengzon Tan, Bing Hui Chen. Investigation of a fluidized bed chemical vapor deposition (FBCVD) reactor towards a large-scale multi-walled carbon nanotubes. International Journal of Engineering Research & Technology. 2014; 3(5): p. 605 - 610.

11. Siang-Piao Chai, Sharif H.Zein, Abdul Rahman Mohamed. A review on carbon nanotubes production via catalytic methane decomposition. NAPCOL. 2004.

12. Jie Liu, Shoushan Fan, Hongjie Dai. Recent advances in methods of forming carbon nanotubes. Advances in Carbon Nanotubes. 2004; 29(4): p. 244 -250.

13. Arash Yahyazadeh, Behnam Khoshandam. Carbon nanotube synthesis via the catalytic chemical vapor deposition of methane in the presence of iron, molybdenum,

and iron-molybdenum alloy thin layer catalysts. Results in Physics. 2017; 7: p. 3826 - 3837.

14. Kenji Hata, Don N.Futaba, Kohei Mizuno, Tatsunori Namai, Motoo Yumura, Sumio Iijima. Water-assisted highly efficient synthesis of impurity-free single-walled carbon

nanotubes. Science. 2004; 306(5700): p. 1362 - 1364.

15. T.Maneerung, K.Hidajat, S.Kawi. LaNiO3 perovskite catalyst precursor for rapid decomposition of methane: Influence of temperature and presence of H2 in feed stream.

Catalysis Today. 2011; 171(1): p. 24 - 35.

16. Avetik R.Harutyunyan, Bhabendra K.Pradhan, U.J.Kim, Gugang Chen, P.C.Eklund. CVD synthesis of single wall carbon nanotubes under “soft” conditions. Nano

Letters. 2002; 2(5): p 525 - 530.

17. Chang Liu, Hui-Ming Cheng. Carbon nanotubes: Controlled growth and application. Materials Today. 2013; 16(1-2): p. 19 - 28.

18. Mukul Kumar, Yoshinori Ando. Carbon nanotube synthesis and growth mechanism. Nanotechnology Perceptions. 2010; 6(1): p. 7 - 28.

19. Poonam Sehrawat, C.Julien, SS.Islam. Carbon nanotubes in Li-ion batteries: A review. Materials Science and Engineering B. 2016; 213: p. 12-40.

20. Sehrawat et al. Carbon nanotubes in Li-ion batteries: A review. Materials Science and Engineering B. 2016; 213: p. 12 - 40.

21. Qing Zhang. Carbon nanotubes and their applications. CRC Press. 2012.

22. http://www.yac.co.jp/en/-/fel/fel1.

23. Chaenyung Cha, Su Ryon Shin, Nasim Annabi, Mehmet R.Dokmeci, Ali Khademhosseini. Carbon-based nanomaterials: Multi-functional materials for biomedical engineering. ACS Nano. 2013; 7(4): p. 2891 - 2897.

24. www.futuremarketsinc.com. The global market for carbon nanotubes-forecast from 2010 to 2024.

1. The Author assigns all copyright in and to the article (the Work) to the Petrovietnam Journal, including the right to publish, republish, transmit, sell and distribute the Work in whole or in part in electronic and print editions of the Journal, in all media of expression now known or later developed.

2. By this assignment of copyright to the Petrovietnam Journal, reproduction, posting, transmission, distribution or other use of the Work in whole or in part in any medium by the Author requires a full citation to the Journal, suitable in form and content as follows: title of article, authors’ names, journal title, volume, issue, year, copyright owner as specified in the Journal, DOI number. Links to the final article published on the website of the Journal are encouraged.